TRAINING LABORATORY FOR THE OPERATIONAL RELIABILITY AND DIAGNOSTICS OF AERONAUTICAL ENGINEERING

Designation.

Organization and carrying out of training sessions, during which the students personally under the guidance of the teachers of the department carry out full-scale or imitation research with the purpose of practical confirmation of certain theoretical provisions of the academic disciplines, acquire practical skills of working with server and multimedia equipment, computation equipment, planning methodic, and experimentation conduction in a specific subject area.

Disciplines taught in the laboratory:

1. Fundamentals of Applied Engineering Technologies.

2. Technical Operation of Aircraft.

3. Reliability of Aeronautical Engineering.

4. Fundamentals of Engineering Diagnostics.

5. Fundamentals of Scientific Research.

6. Diagnosis and Control Systems of Aircraft Technical Condition.

7. Information Technologies of Aeronautical Engineering Maintenance Processes Ensuring.

In the field of reliability the calculations of reliability of the systems and products of aeronautical engineering are carried out for all types of aircraft of the registry park of Ukraine.

At the same time, higher education applicants use the methods of information gathering and accounting developed by the staff of the department and the proposed methods of constructing mathematical models of reliability of aviation products based on statistics coming from all operating enterprises of Ukraine.

To substantiate the relevance of the research, the results of the reliability analysis are used in carrying out the qualification work of the candidate of the “Master’s Degree”.

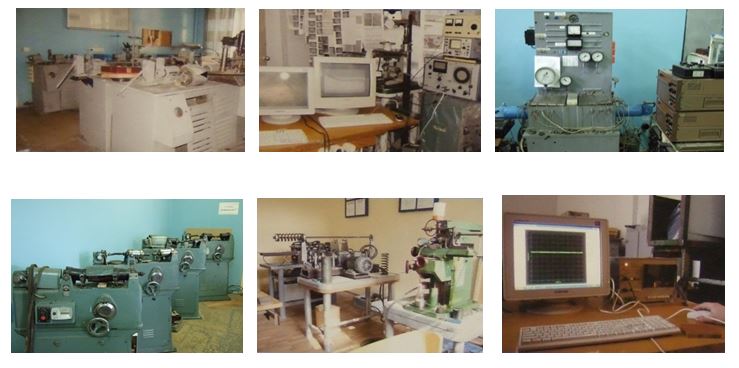

The Laboratory for the Operational Reliability and Diagnostics of Aeronautical Engineering is equipped with the complexes of equipment such as:

ИКУ-1 (indicator of ultrasound vibrations);

endoscopes of a wide variety of purpose by type;

installation БАРС-3 for determination of the metal composition;

instruments ПОЖ-М and ПОЗ-Т.

The laboratory performs more than 20 laboratory works in the following disciplines: “Fundamentals of Engineering Diagnostics”, “Diagnosis and Control Systems of Aircraft Technical Condition”, “Methods and Means of Diagnosis”.

Computer room

The computer room provides students with the opportunity to complete course projects and work in electronic form.

Also more than 100 laboratory works (research of certain phenomena and processes, simulation and mathematical modeling of systems and processes of aircraft maintenance) are carried out in the computer room, as well as the test and module check works in the following disciplines:

1. Fundamentals of Engineering Diagnostics.

2. Reliability of Aeronautical Engineering.

3. Operational Documentation (ICAО Doc 9760).

4. Technical Operation of Aircraft.

5. Fundamentals of Applied Engineering Technologies.

6. Fundamentals of Scientific Research.

7. Information Technologies of Aeronautical Engineering Maintenance Processes Ensuring.

8. Diagnosis and Control Systems of Aircraft Technical Condition.

STUDY LABORATORY for AIRCRAFT structures ENGINEERING

Designation.

Organization and carrying out of training sessions, during which the students personally under the guidance of the teachers of the department carry out full-scale or imitation research with the purpose of practical confirmation of certain theoretical provisions of the academic disciplines, acquire practical skills of working with planning methodic, and experimentation conduction in a specific subject area.

Disciplines taught in the laboratory:

1. Fundamentals of Manufacture and Repair Technologies for Aircraft.

2. Material Science and Technology of Structural Materials.

3. Innovative Technological Processes in the Manufacture and Repair of Aircraft.

4. Fundamentals of Engineering Diagnostics.

5. Defectology and Non-Destructive Methods of Control.

6. Repair of Technological Equipment of Compressor Stations.

7. Manufacture and Repair of Gas Turbine Installations and Compressors.

Applicants can perform:

physical (full-scale) study of the processes of friction and wear of the aircraft and aeroengine parts and units, damages; and to develop technologies for restoration of the aeronautical engineering parts;

evaluation of rheological and tribological properties of lubricants;

assessment of tribological characteristics of coatings and materials under different types of loading (contact dynamic loading, fretting corrosion, unidirectional friction, reversible friction);

estimation of the resource of aviation hinge bearings;

investigation of the processes of surface and volumetric destruction of structure elements of the aircraft and aeroengines by methods of defectoscopy and structuraloscopy.